- Home

- Brand

- Air Lift (37)

- Airmaxxx (120)

- Arb (31)

- Bc Fabrication (41)

- Below0ac (45)

- Chassis Tech (76)

- Chicago Pneumatic (25)

- Craftsman (40)

- Dewalt (63)

- Hornblasters (23)

- Ingersoll Rand (49)

- Makita (22)

- Master Airbrush (53)

- Maxline (37)

- Milwaukee (36)

- Porter-cable (43)

- Quincy Compressor (27)

- Suncore Industries (26)

- Viair (246)

- Vixen Air (24)

- Other (1836)

- Model

- Phase

- Portability

- Power Source

- 30mpa / 4500psi (2)

- Air (2)

- Air Powered (14)

- Air-powered (2)

- Battery (77)

- Battery / Cordless (7)

- Battery Powered (13)

- Cigarette Lighter (3)

- Corded Electric (234)

- Cordless (6)

- Cordless Electric (2)

- Electric (74)

- Gasoline (2)

- Hard-wired (27)

- Hybrid (2)

- Plug-in (10)

- Pneumatic (13)

- Rechargeable Battery (2)

- Wall Outlet (4)

- corded Electric (3)

- Other (2401)

- Voltage

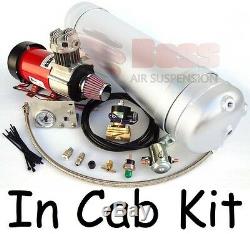

BOSS PX07 In Cab Kit for Air Bag Suspension Compressor Gauge Tank Switches

This is a complete heavy duty BOSS in cab kit for air bags. You dont need anything else to pump up air bags in your car. This is kit is complete.

Here's how it works. The BOSS PX07 compressor fills a 3 Gal (9 litre) alloy air tank and the pressure switch stops and starts the compressor so it maintains the desired working pressures (110-135 psi). There is an electric valve and when activated by the switch on the gauge panel it opens and allows air to pass from the tank to both bags. Because there is a good supply of high pressure the bags inflate quickly and the car lifts quite fast (like in about 1-2 seconds). And then with the air dump switches on the Gauge panel you can let each bag down separately to your desired levels - you can see each of their pressures on the gauge as it has 2 needles. With kit you could also plug in air tools, tyre inflation kits, run air lockers, etc. Here's what you get in this really nifty kit... 1 x PX-07 3/4 hp 12V BOSS Air Compressor. 1 x Stamped stainless steel gauge panel. 2 x Pneumatic Push Buttons for dropping each bag. 1 x 12V momentary switch for compressor. 1 x BOSS 200psi Dual Needle back-lit Gauge.10 meters of 1/4 J844 DOT Airbrake line. 2 x 3/8 check valves. 1 x pressure switch 110 - 135 psi. 1 x water release valve.

1 x 700mm Braided air line (compressor to tank - manages heat). 1 x Flare Fitting for braided Line. Spare Bungs to fill empty ports on tank.

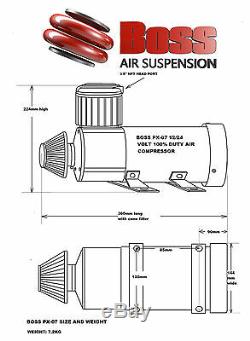

5 x 1/4 push connect fittings. 4 x 1/4 female push fittings for gauge and buttons. If you need to ask someone about whether this item is right for you or if you have any questions at all then please just call me on. This is large man size PX07 Boss Compressor by BOSS. The BOSS PX07 Compressor is regarded as the biggest and best 12V or 24V Compressor on the market. It's grunt easily doubles that of the biggest ARB unit and we challenge any critic to present us with a faster unit.Runs on 12V and 24V. 170 Litres free flow (3.5 cfm). Happily pumps to 200 psi but safe regular work loads to 150 psi. 100% Duty Cycle (which means it just keeps going rather than cutting out).

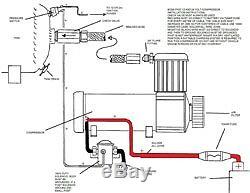

60 Amp max start up current at pressure. You cant have power without Amps. No Oil - means it can be mounted upside down or on its side. Air Filter maybe cleaned and mounted in a different location like away from water. Re-buildable which means we stock servicable parts like pistons, rings, head and brushes so you can keep this going inexpensively for years to come. Being 3/4 HP this unit averages 560 Watts.That's about 6 spot lights so it deserves respect. High capacity power leads via a high capacity relay must be used. Voltage drop results from thin wires and long wires. Lower voltage means significantly higher amps and this generates heat and burning out of any electrical motor.

The rule of thumb is the longer the wire the heavier it needs to be. We want to see wire at least as thick as a pencil be used and your relay should be at least 100Amps.

We supply wiring instructions so anyone can set up this BOSS compressor. The unit is primarily 12V but the 4WD event competition guys run 24V into this un-modified compressor and yes it does run twice as fast when you do this.This compressor has a rebuild kit available and that includes new brushes, pistons and seals. All the stuff you could possibly need to keep your compressor going for many years to come.

And here's the link to our wiring kit for this big brute... Ensures it reaches its full potential.

This kit comes with the BOSS aluminium 3 Gallon / 9 Litre Tank as pictured here. The mounting legs clamp on so you slide them along the tank and rotate the tank so the water drain port is at the lowest point, etc. It only took 100 years for someone to think of that.. Anti-corrosion is a very valid concern for tanks because all compressors create moisture and water builds up in tanks. This is a tank ideal for tyres and tools.

Easily run nail guns and rattle guns from this tank and even blow the dust off with one of those trigger nozzle thingies. Still good for diff locks too. The dimensions are 46cm long x 17cm wide and allow 3cm for the mounting legs. There are 2 x 3/8 NPT ports and 3 x 1/4 NPT ports.

We also have a budget set up with a smaller compressor and no tank for those customers who just want to run air bags only (mind you the smaller PX02 will still do tyres and lockers). This is a big man-sized compressor. 224mm tall to top of cylinder head. 360mm long with filter attached. All of our gear may be picked up from our official BOSS development center in Labrador on the Gold Coast or we can send anywhere in Aus (or with express options) or Worldwide at affordable rates.

If you have an ABN we can help you with trade prices. Almost every air bag application we do is bolt in.

No welding or cutting or drilling. We make that a mandatory requirement when we develop a new kit. And we will make sure we do better.

We wont be beaten on price, quality or service. Happy customers is our key to success. People often ask why or how are we so much cheaper than Firestone. So our costs are way down and if we charged Firestone prices we would be ripping you off. Our bags are not permanently attached to the mounting brackets.That means you can replace a bag if you have to without the costly new brackets as well. No need for qualified installers, anyone can fit our gear and its easy. We talk with farmers, tradies and travelers every day about their load carrying and air system needs and we take pride in making our mark on Australia.

We have been doing air suspension for over 15 years and have over 20,000 Aussie customers out there running BOSS air suspension products. Over the years we make improvements where we can and so by now we have become a market leader recognised for having the best product at the best prices.

BOSS also have a development center in Canada looking after our Canadian and American interests. We have a lot of exciting vehicle applications in the USA that eventually filter through to Australia and other parts of the world and so we have a very extensive range which includes all the American pick ups as well as the old classic cars like Chev and Buick. At BOSS we dont copy others - To begin with we dont trust the others to get it right. But more importantly the others dont have anything to copy.

BOSS are the first to get hold of new vehicle models and get kits to market having tried and tested them, fully getting to understand the vehicle and the engineering required. As such BOSS have the widest range of applications for Australian and USA markets and we are onto all the new models even before they are released. BOSS have the most comprehensively wide range of accessories as well. All of our air compressors can be rebuilt and we stock those parts.

We have tanks, pressure switches, water filters, braided lines, digital pressure gauges, everything for in car operation of your bags, the list goes on and on. BOSS air bags are manufactured in our BOSS factory with our own machines to our own exacting standards and specifications.

We strongly believe it's the only way of maintaining strict control over the bags. Here are some interesting facts...

It takes over 20 minutes for each bag to go from the raw un-cured blended rubber to a cured air bag. 1 machine can only make 1 bag at a time. Its not just the thickness of the rubber that gives the bag its strength but also the angle of the reinforcing cords and design of the woven beads.

The proprietary ballistic material used for the woven reinforcing on the airbag wall, along with the specific spacing and angle of the weave, is what gives our air bag its unique strength. The bead ring ends of the bag are constructed of 4 Hi-tensile cords at each end, ensuring that the top and bottom hold their shape and cant be pulled away from the Aluminium clamping ring.

The center of the air bag (the part of the bag with the most stress) is constructed using 9 strands of Hi-Tensile steel to form an indestructible center support. Our competitors's bags have less than half these strands.

The BOSS airbag machines are operated at over 400psi while the curing process is taking place with very high heat. There's an internal bladder pushing the airbag case into the mould ensuring consistency throughout the airbag wall. Each air bag machine has over 50 tons of clamping pressure on the mold during curing. Effectively these are desperately over engineered as there's no way you could ever exert over 50t and 400 psi on a bag in your vehicle.

The factory tests selected bags to destruction within a controlled chamber to ensure continued bag quality and identify possible ways to constantly improve the design and technique. We have just recently released the exciting new EX-2 Bags. They have a 5 year leak free guarantee. Tooling was modified to provide for a heavier and wider rim width.BEWARE: Some other brands use crimped-on end caps. Crimped or Banded air bags are prone to popping the end caps out at anything over 100psi and often simply pull the end caps out when the bag is fully extended. BOSS air bags are undeniably the strongest in the automotive industry and exceed any other air bag brands by nearly double. We pride ourselves in looking after everyone. Even if you have had your gear for years we will still look after you because who knows, our next customer could be your friend you refer to us.

Ver 100 different air bag leaf and coil load assist kits. BOSS does coil replacements kits. BOSS does full air suspension systems. BOSS does package deals with different in cab and compressor options. And of course, BOSS does air suspension for Harley Davidson bikes...

So you see BOSS is 100% focussed and committed to delivering all the best gear. There is a selection of our other popular accessories and add ons. Like we said, no one else offers such a huge list of optional bits. The item "BOSS PX07 In Cab Kit for Air Bag Suspension Compressor Gauge Tank Switches" is in sale since Thursday, March 13, 2014. This item is in the category "Vehicle Parts & Accessories\Automotive Tools & Supplies\Air Compressors".

The seller is "bossproducts" and is located in Moreton, QLD. This item can be shipped worldwide.- Manufacturer Part Number: BOSS PX07 Kit

- Brand: BOSS